Introduction

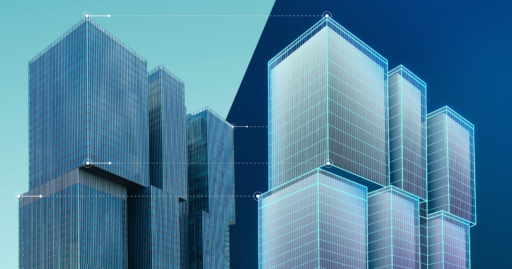

Gemelos digitales, or digital twins, are exact replicas of physical objects that can be analyzed and used to improve their real-world counterparts. Digital twins technology allows for the prediction and monitoring of the performance of physical objects, both existing and hypothetical.

How can digital twins enhance efficiency and predictability in various industries?

“It is an exact replica that can be analyzed and used to improve its real-world counterpart.” – Luisa C., Architect

What are Digital Twins?

Digital twin technology utilizes data from the real world to create virtual representations that can predict and improve performance. They integrate the Internet of Things, artificial intelligence, and software analytics to enhance outcomes.

Digital twins provide insights into the functioning of physical objects in real-world . They can analyze the performance of buildings, determine infrastructure requirements, and predict energy demand patterns. These data are then sent to a system that processes and applies them to the digital twin.

Once the data is available, the virtual representation can be used for testing, performance analysis, and potential improvements. Unlike traditional simulations, digital twins offer scalability and real-time data integration.

Some notable examples include jet engines, wind farms, and even whole cities. By leveraging digital twins, businesses can benefit from improved modeling and design, a better understanding of performance, and the ability to make data-driven decisions.

The Functioning of Digital Twins

Digital twins are essentially computer programs that use real-world data to create virtual representations that can predict the performance of an object or a process.

By utilizing digital twin technology, you can gain valuable insights into your manufacturing processes and equipment performance.

- Monitor your equipment in real-time to ensure optimal functioning and the correct product lifecycle.

- Analyze real-time data to identify areas for improvement and increase efficiency.

- Gain a comprehensive understanding of how your entire plant is functioning.

With the expansion of IoT, AI, VR, and cloud computing, digital twins are becoming increasingly sophisticated and capable of providing valuable insights across various industries, you can streamline your product development and design processes, improve manufacturing efficiency, and enhance maintenance operations.

The technology of digital twins is continuously evolving and acquiring new capabilities through machine learning. This means that digital twins can generate knowledge to improve products and optimize various processes. They facilitate automation, data sharing, and the integration of manufacturing processes, reducing risks and enhancing efficiency.

Applications of Digital Twins

When can a digital twin be used and in what industries are they utilized?

Digital twins can be used at various stages in the construction industry to monitor existing elements, reduce maintenance costs, and predict failures. For example, they can help in supervising existing products to reduce maintenance costs and complexity by predicting failures before they occur. They are also effective in reducing unplanned downtime due to failures, minimizing maintenance costs, and ensuring production targets are met.

In the automotive industry, digital twins can be utilized to improve performance, increase production efficiency, and optimize services. For instance, they can be used to monitor the performance of vehicles, predict maintenance needs, and reduce the risk of unplanned downtime. This can lead to cost savings and improved overall operational efficiency.

In the healthcare sector, digital twins can track health indicators and generate key patient information, leading to better predictive and preventive care. For instance, they can be used to monitor the performance of medical equipment, predict maintenance needs, and reduce the risk of unplanned downtime. This can result in improved patient care and reduced operational costs.

In urban planning, digital twins can provide real-time spatial data and incorporate augmented reality systems for the development of new cities. For example, they can help in monitoring existing infrastructure, predicting maintenance needs, and reducing the risk of unplanned downtime. This can lead to more efficient and sustainable urban development.

The Future of Digital Twins

As technology continues to advance, digital twins will play a crucial role in industry development, enabling automation, data-driven decision-making, and risk reduction. They will have a wide range of applications and will continue to evolve and improve with advancements in technology.

By leveraging the capabilities of digital twins, industries can enhance efficiency, predict and prevent failures, and drive innovation. Embracing digital twins can lead to improved outcomes and a competitive edge in today’s rapidly evolving business landscape. With machine learning, digital twins will be able to generate even more valuable insights and optimize various processes for better outcomes.

Conclusion

Digital twin technology offers a wide range of benefits for businesses across various industries. By providing a virtual replica of physical assets, it allows for real-time monitoring, analysis, and optimization. This can lead to improved operational efficiency, reduced downtime, and cost savings.

Ready to harness the power of digital twins for enhanced performance?

Let’s embark on this journey!