Evermore people are intending to realize their ideas through projects, and as a result, the use of practices which follow the values of the Agile Manifesto in planning and organizing tasks no longer applies only to large companies or in software development- on the contrary, it is possible to apply them to any type of activity, and even in everyday life.

The Kanban method has become incredibly popular as an alternative path to Agility as it is flexible and can be adapted quickly regardless of the type of production process, is compatible with the simplest or most complex administrations, and can be integrated with other Agile methodologies without compromising them, such as Scrumban. Kanban requires great self-discipline and an even greater effort in a cultural respect, as its use relates to more than the mere mechanics of visualizing and measuring, unlike in Scrum, where the values are more explicit due to the feedback that is already integrated.

The Origins of Kanban methodology

Kanban is a combination of two Japanese words: kan, which means visual, and ban, which means card.Together they form “visual card”, indicating their nature of making the visibility of an entire drag system that favorably increases the quality of a job possible.

The first Kanban System was developed by Taiichi Ohno in his search for a Lean Manufacturing model that, together with Goldratt’s Theory of Constraints, are fundamental in understanding the importance of being able to control the entire value chain from supplier to end consumer through efficient, ethical and socially responsible production.

Kanban, as a method, was first formulated and documented by David J. Anderson, a forerunner of its use in the IT sector, in his book: Kanban: Successful Evolutionary Change for Your Technology Business (2010), highlighting its minimal resistance to change while maintaining a sustainable pace for the workers involved.

Fundamental principles

- Visualize the production flow

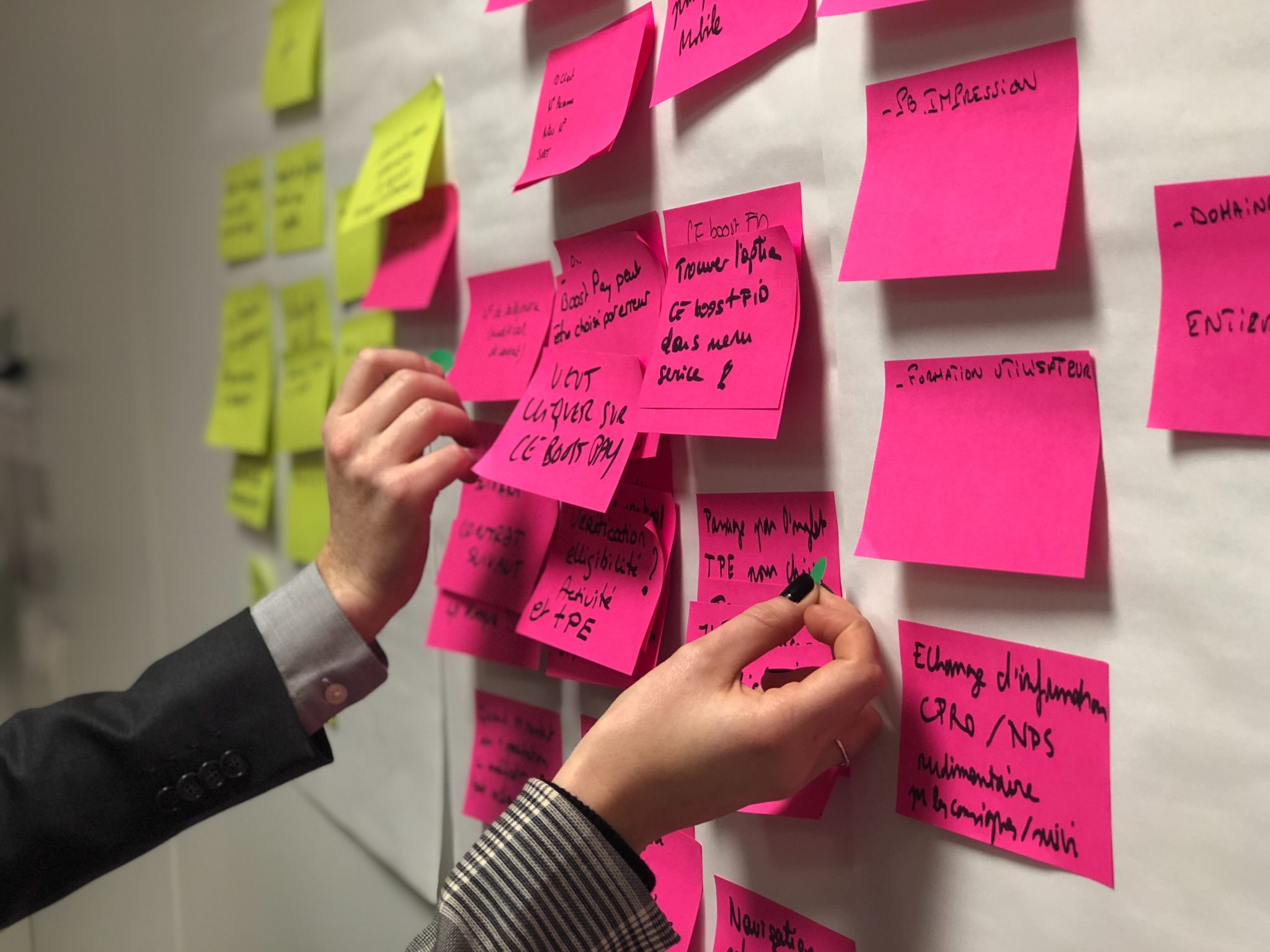

The actual process becomes apparent through shared modifications via a dashboard which is either physical (sticky notes) or electronic (management software elements: Jira, Trello, ClickUp, etc.). Each team is in charge of determining its structure or the different areas of division, which must identify and add value to the entire journey from the beginning of a task until its completion and not requiring any further attention. It does not matter if the work is related to a product, a service or any other activity. In short, all the tasks are organized into: Backlog, WIP (work in progress) and Done, with acknowledgements and modifications specifically adapted for each project.

It is obvious that the process for some demands will be different, therefore, so will the colors of their representative cards. All cards must be concise and easily understandable, and may incorporate other markings with specific annotations (delivery date, stipulated processing time, being blocked, and urgency, among other relevant information). The entire composition of this dashboard makes it easy to track the current status of the workflow that passes through each element, including potential problems generated by possible accumulations that slow down progress continuity.

- Limit work in progress

Taking into account the application of Little’s law, it is important to know or establish the minimum and maximum capacity of the production process to avoid reaching the upper WIP limit. A balance is always better: a very high WIP leaves work idle while a very low WIP leaves people idle.

The first column of the board shows a queue where the tasks that we accept will be accumulated, and the last column shows a cumulative buffer of finished tasks ready for the next activity, if there is one. Other intermediate stages may also require a buffer to decouple from the next or previous area, changes necessary to avoid degrading the process, in which case it is essential to know how to separate the urgent from the important, which must be made visible through extensions of the same grid.

When the maximum capacity is exceeded, a visual alert is received, which is a warning to reorganize the structure so that it is possible to respond to a production process with higher or lower demand than usual. When demand drops, analyze what happened and why. Equally when the output buffer is full, it is a signal to stop taking on new tasks.

In summary, the next thing to do is decide which tasks to begin from the backlog, prioritizing according to real-time needs, always with the possibility and ability to respond to unforeseen events. Having indicators to detect possible failures or bottlenecks in the system and being able to act accordingly to make improvements is the greatest advantage of the system.

- Manage the flow

In relation to time and constant process improvement, made easily visible through emergency alerts. There is always a tendency to think that everything is urgent because the routine is consuming us and setting a time limit, and for this reason, it is more and more prevalent that the truly most urgent tasks are not prioritized. In the rush the resolution of basic tasks, which move us towards the central objective that we want to achieve, ends up being abandoned, so it is necessary to incorporate this as a permanent exercise so as not to be running continuously behind schedule.

With regards to management practice, it is possible to follow two common metrics. The first is delivery time, as fewer tasks in the process leads to a faster flow, thus shortening the delivery period. The second is performance, completing a certain amount of tasks in a given period. A pull or JIT (just-in-time) system is established because the demand “pulls” the production avoiding excess, so only what is necessary, not what is established in a plan but what is most demanded, is done, as well as preventing flaws by stopping the process to identify the reason, correct it, and start over. It is a way to ensure you don’t repeat the same mistake, or at least make it for the same reason.

With internal coordination of tasks (as a team), time will be better planned and managed. It will be possible to attend to and greatly reduce the number of urgent and important tasks, and to reach completion better.

“Stop starting, start finishing!”

Before starting, define what is expected in the project (the mission) and from there on, all the short or long-term goals and objectives to strive towards will emerge: How do I want it to be? Who do I want it to arrive to? What will be the characteristics that define its identity? Applying Kanban requires making the process policies explicit to all members, promoting debate based on objective data and thus having greater confidence in the implementation of the SLA (Service Level Agreement) established in retrospect to the metrics benefitting the process. The Kanban method is a constant search for collaboration and experimental evolution, a visual process-management system that tells us what to produce, when to produce it, and how much to produce.

About the Author

Fabrizio Amelotti is a Full-Stack Developer with 10 year experience in the IT and software development world. Fabrizio is a technical leader able to move forward a simple idea until the implementation and beyond.